Bronze Bushing: The Key to Reducing Friction in Industrial Solution

Bronze Bushing: The Key to Reducing Friction in Industrial Solution

Blog Article

Every Little Thing You Required to Know Concerning Bearing Bushings

Birthing bushings might seem like a little component, but their role in numerous mechanical systems is crucial. From reducing rubbing and put on to supplying stability and support, bearing bushings play a substantial duty in making sure smooth operation and longevity of machinery. Recognizing the different types of birthing bushings, their value, aspects to think about when choosing them, as well as their installment and maintenance, can be overwhelming. In this write-up, we will unravel the keys of bearing bushings, look into their various kinds, and check out the factors to take into consideration when choosing the right one for your certain application. So, whether you are a mechanical engineer, an upkeep service technician, or simply interested about the internal workings of equipment, hold tight as we begin on this fascinating trip right into the world of birthing bushings.

Types of Birthing Bushings

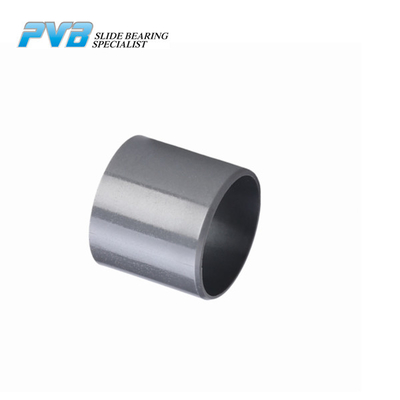

Among the most commonly made use of kinds of birthing bushings is the ordinary bearing bushing. This type of bushing contains a cylindrical sleeve constructed from a low-friction product such as bronze or plastic. Plain bushings are straightforward in style and give efficient support and lubrication for revolving or sliding shafts.

One more kind of bearing bushing is the flanged bushing. bronze bushing. Flanged bushings have a flange or collar on one end, which helps to safeguard the bushing in position and protect against axial motion. These bushings are usually used in applications where there is a demand for additional stability and assistance

Self-lubricating bushings are additionally widely utilized in numerous industries. These bushings are made of materials such as bronze or graphite, which have self-lubricating homes. This eliminates the requirement for external lubrication and decreases upkeep requirements.

Furthermore, there are round bearing bushings, which can suit misalignment and angular motion. These bushings have a spherical internal surface area that enables smooth rotation and movement in multiple directions.

Value of Bearing Bushings

Birthing bushings play a crucial role in guaranteeing the smooth procedure and long life of equipment and tools by giving assistance, reducing friction, and improving security in between relocating components. These elements, commonly constructed from steel or polymer products, are put right into the real estate or birthed of a birthing to support and direct the turning shaft or other moving parts.

One of the key features of birthing bushings is to supply assistance. They assist distribute the load evenly, preventing excessive stress on specific components and making sure that the weight is appropriately dispersed. This support helps to prevent early wear and damages to the machinery.

Additionally, bearing bushings improve security. They aid to maintain the alignment and positioning of the moving parts, stopping any kind of undesirable movement or vibrations. This stability is important for the appropriate performance of the equipment and makes certain the safety of the operators.

Elements to Think About When Selecting Bearing Bushings

When choosing birthing bushings, it is important to meticulously take into consideration numerous variables to ensure optimum efficiency and durability of the equipment or devices. Among the primary elements to think about is the load capacity of the bearing bushing. It is essential to choose a bushing that can handle the expected lots without experiencing too much wear or failing. The operating conditions ought to also be considered. Variables such as temperature level, speed, and lubrication demands can impact the performance of the bushing. High-speed applications may require self-lubricating bushings to lower rubbing and heat generation. Additionally, the sort of movement, such as linear or rotational, must be thought about when selecting a bearing bushing. Various types of bushings, such as sleeve, flanged, or drive, are offered to accommodate details kinds of motion. An additional essential factor is the compatibility of the bushing product with the mating shaft or real estate. The material needs to have great wear resistance, reduced friction coefficient, and compatibility with the lubricant utilized. Lastly, the price and availability of the bushing need to be thought about to guarantee it fits within the job's spending plan and timeline. By meticulously thinking about these variables, one can make an informed choice and select the most click here for more info ideal bearing bushing for their application.

Installation and Maintenance of Bearing Bushings

To guarantee optimal performance and lengthen the life-span of birthing bushings, appropriate setup and regular upkeep are crucial. Inappropriate installment can lead to premature wear, enhanced friction, and lowered performance of the bearing bushings.

Routine upkeep is vital for the smooth operation of bearing bushings. This consists of regular evaluations to check for indicators of damage, wear, or imbalance. It is very important to address any concerns immediately to avoid further damages and potential failing of the bearing bushings. Lubrication is one more crucial facet of maintenance. Correct lubrication assists to reduce rubbing, dissipate heat, and shield against deterioration. It is very important to use the ideal lube and use it according to the maker's recommendations.

Along with routine examinations and lubrication, it is also suggested to occasionally clean the bearing bushings to eliminate any kind of dust, debris, or pollutants that might have accumulated (bronze bushing). This can be done using a solvent or cleansing representative find here and a soft brush or towel. It is essential to prevent making use of rough chemicals or abrasive materials that might harm the bearing bushings

Usual Issues and Troubleshooting With Bearing Bushings

One of the most typical challenges encountered with bearing bushings is correct positioning within the housing or shaft. When a bearing bushing is not aligned correctly, it can lead to too much wear, boosted friction, and premature failing of the bearing bushing.

One more usual issue with birthing bushings is insufficient lubrication. Normal lubrication maintenance should be brought out to ensure that the bearing bushing is appropriately lubed.

Additionally, contamination can present a major problem for bearing bushings. Dust, dust, wetness, and various other pollutants can create and enter the bearing damages. Regular cleansing and inspection of the bearing real estate and shaft are necessary to stop contamination. In instance of contamination, the bearing bushing ought to be extensively cleaned and checked for any indications of damages.

Conclusion

From reducing friction and use to providing stability and assistance, birthing bushings play a significant function in ensuring smooth operation and durability of equipment.One of the most commonly utilized kinds of birthing bushings is the plain bearing bushing (bronze bushing).One more kind of birthing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which helps to protect the bushing in location and protect against axial movement. When a bearing bushing is not lined up properly, it can lead to too much wear, increased friction, and premature failure of the bearing bushing

Report this page